Printing, exists in every corner of our lives, books need to be printed, brand packaging boxes, art books and so on. Once upon a time, the dissemination of cultural ideas need printing, is the invention of printing, so that we began to enter the era of rapid cultural exchange. once upon a time, there is only one printing method. Today, the Internet continues to grow, we can get away from paper books to access the culture and the information of the times, but printing will not disappear because of the dissemination of data on the Internet cloud, because people still need books for the healing of the soul. Although the digital transformation has affected some of the needs of the printing industry, printing technology still has a broad and far-reaching impact in many areas, especially in branding, packaging design, customized products, artistic creation and environmental protection. As technology advances, the printing industry continues to innovate to meet the diverse needs of modern society with different types of printing. Today, Xinyi Printing is going to popularize the types of printing for you. First of all, let’s first understand the origin of printing!

The origins of printing

The invention and development of printing is a long and legendary process. The origin of printing can be traced back to ancient China. The earliest form of printing was woodblock printing, which is a method of copying by engraving text or patterns on a wooden board. The earliest woodblock printed books appeared in the Han Dynasty. Although the printing at this time was not perfect, it laid the foundation for more advanced printing technology later.

1、 The invention of printing in China

(1)The invention of woodblock printing

The origin of printing can be traced back to ancient China. The earliest form of printing was woodblock printing, which is a method of copying by engraving text or patterns on a wooden board. The earliest woodblock printed books appeared in the Han Dynasty. Although the printing at this time was not perfect, it laid the foundation for more advanced printing technology later.

Woodblock printing: In the Han Dynasty, woodblock printing was mainly used to spread Buddhist classics. By the Tang Dynasty, woodblock printing had become mature. Buddhist classics in the Tang Dynasty, such as the Great Prajna Sutra, were produced using woodblock printing technology. During this period, the speed and popularity of book reproduction were significantly improved.

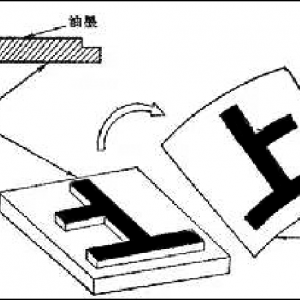

(2)Invention of movable type printing

Bi Sheng (c. 1041-1048 AD) was an inventor in the Northern Song Dynasty of China, who is widely regarded as the inventor of movable type printing. Bi Sheng’s invention had an important influence on the subsequent development of printing.

Invention process: Bi Sheng used clay to create characters that could be taken out and reassembled individually, and placed these characters in a printing frame to reproduce the text by pressing. This is the earliest movable type printing technology in the world. He faced many technical difficulties when inventing movable type printing. In order to ensure the neat arrangement of the blocks, he designed reusable clay blocks and made these blocks by carving each glyph. Each block can be disassembled and rearranged, allowing for flexible combinations of text.

Although Bi Sheng’s invention was technically revolutionary, it was not widely used because clay movable type was fragile in actual operation and not suitable for large-scale production. Nevertheless, Bi Sheng’s movable type printing laid the foundation for the emergence and development of metal movable type later.

Mengxi Bitan: Bi Sheng’s movable type printing was first recorded in Mengxi Bitan by Shen Kuo, a scientist in the Northern Song Dynasty. Shen Kuo spoke highly of Bi Sheng’s movable type printing, believing that this technology had the ability of “clairvoyance” and could produce books on a large scale.

Types of printing methods

Traditional printing method

1、Offset Printing:

offset printing, is one of the most commonly used printing methods. It was developed from early lithography and has since been improved to use metallic zinc or aluminum as the plate material. It is characterized by the printed and unprinted parts being on the same plane, using the principle of repulsion of oil and water to print the image onto a rubber offset cylinder, which in turn prints the image onto the paper. Offset presses have multiple printing units that can transmit different colors.

Advantages: Lithographic printing has accurate color registration, easy plate making, low cost, soft tones and rich layers. Its output is more than any other printing method.

Disadvantages: Due to the influence of water and glue during printing, the color reproduction power is reduced and the vividness is lacking. Plate ink is thin (only 70% of the capacity to show, so the light box posters must be printed on both sides to strengthen its color). Special printing applications are limited.

Applications: posters, short price, manuals, newspapers, packaging, books, magazines, calendars, other related color printing and large quantities of printed matter.

2、Letterpress Printing:

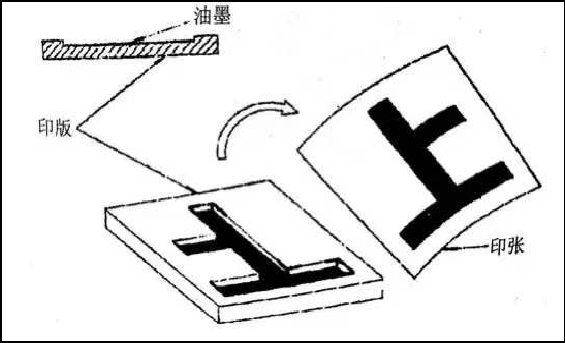

Letterpress printing was first invented and is one of the oldest printing techniques, characterized by the coloring of images and text on the raised part of the page and then printing directly onto the paper. It is applied like a stamp, with the raised areas inked and printed directly on the substrate. Advantages: letterpress printing plate plate material in various forms, applicable to a wide range of substrate materials, and letterpress printing machine structure and operation is relatively simple. Disadvantages: this printing method can not print multi-layered, colorful prints, its expressive power is greatly restricted, while the printing of large areas of monochrome prints have advantages. Characteristics: due to the printing pressure, the paper back of the printed matter has a slight print mark raised, lines or dots edge part of the neat, and the printing ink in the center part of the light appears, the raised edge of the print pattern by the pressure of the heavier, and thus have a slight print mark raised.

Letterpress printing can be divided into three types:

(1). Flat-pressing printing This is a very traditional printing method, similar to letterpress printing. The press consists of the base of the printing plate and the press platform. When the base of the printing plate is fixed, the surface of the printing plate is uniformly inked, the press platform presses the printing material downward in the direction of the printing plate, and the graphics on the printing plate are then transferred to the substrate, which completes the printing process.

(2). Cylinder printing Differing from flat-pressing, the press platform is changed to a cylinder. When the printing plate is fixed, the surface of the printing plate is uniformly inked, and the printing cylinder carries the printed material with it as the cylinder moves on the substrate, and the graphics on the printing plate are then transferred to the substrate, and the printing process is completed.

(3). Rotary printing adopts the cylinder printing plate and the cylinder imprinting with an independent inking system, and the substrate is transferred to the substrate when it passes through between the two cylinders under the force of the imprinting cylinder, after the printing is completed, and then the printing is completed, and then the printing is completed. When the substrate passes between the two cylinders, the graphic on the printing plate is transferred to the substrate under the force of the embossing cylinder. Rotary printing is suitable for mass production.

3、Gravure Printing:

Gravure printing is a fast growing printing method, which is the opposite of letterpress printing in that the imprinted portion is concave to the plate and the non-imprinted portion is smooth. The concave part is used to fill the ink, the ink on the surface of the printing plate before printing scrape clean, put on the paper and apply pressure, the concave part of the print is transferred to the paper. 1, book publishing: gravure printing paper color number can reach 6 ~ 10 colors, the world’s leading media groups and publishers many of the use of gravure printing technology to print books, periodicals and magazines. Such as Germany Betas (Bertelsmann), Holtzbrinck Publishing Group (Holtzbrinck), as well as the United States, the third-largest commercial printer Quad / Graphics Corporation, France’s largest publishing company, Achert Book Group (Hachette), etc. 2, product packaging: gravure printing using roll materials, packaging materials, printing widths of up to 1500mm, paper packaging and plastic film packaging used more. Such as: food packaging boxes, tobacco products, boxes and cans, glass containers outside the packaging materials.

4、Screen Printing:

Screen printing, that is, a printing method using a screen as the plate. The specific method is to make two parts on the printing plate, the graphic and the plate film, the role of the plate film is to prevent the passage of the ink, while the graphic part of the ink through the external force of the scraping pressure will be funneled to the substrate, so as to form a printed graphic. The principle is to dig and cut holes in the flat plate, and then apply ink, so that the ink leaks through the holes and prints on the substrate.

Advantage: Screen printing can not only paper as a carrier, but also plastic products, metal or leather products and other materials as a substrate for printing, adapt to a wider range. From large-scale advertising to business cards can be printed, and can be printed on paper, cotton, silk, plastic, glass, wood, metal and other materials on the substrate. For example: the printing of fonts on our common car, the printing of graphics on the outer box, etc., especially in the packaging container bottle printing has advantages.

Disadvantages: in terms of the quality of printed matter, the quality of screen printing can not be better than offset printing, due to the use of screen printing screen and squeegee operation, especially when operated manually, because of manual operation of screen printing may appear a lot of waste products and defective products. Secondly, mass production of screen printed products is relatively difficult, in offset printing in a few minutes to complete the prints, screen printing in about double the number of hours. Four-color overprint gradient image in screen printing and can not be realized as freely as offset printing.

Modern printing methods

1、Digital Printing:

Principle: Directly from the digital file through the printing device will be printed directly to the paper or other materials, without the need for printing plates.Characteristics: No need for plates, suitable for small quantities, diversified needs, rapid production.

Applications: personalized books, business cards, posters, packaging, etc

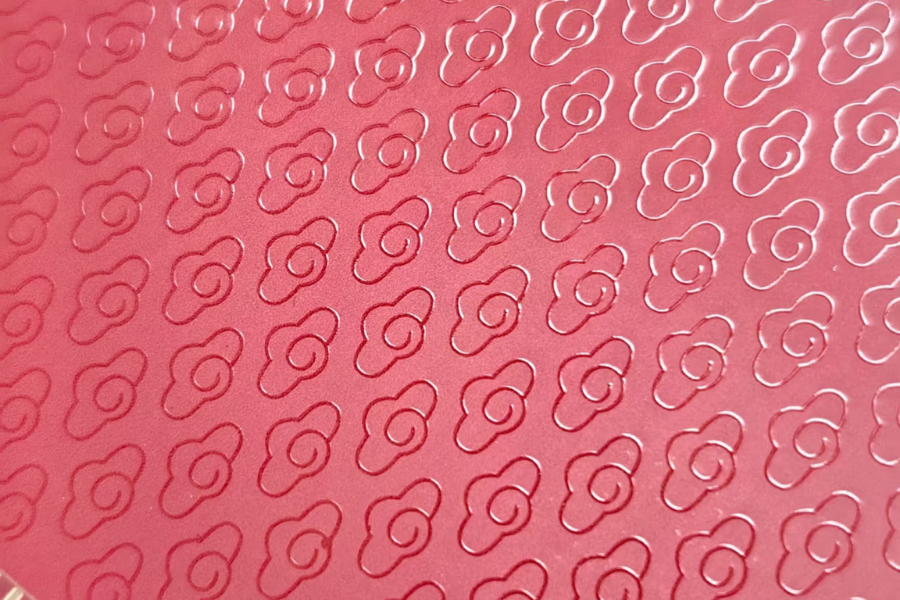

2、UV Printing:

Principle: Using UV-curable ink, the ink is cured by UV light and dries immediately.

Features: High quality and durability, able to print on different materials.

Applications: Printing on plastic, glass, metal, wood and other surfaces.

3、Laser Printing:

Principle: Burning the image or text onto the printing plate through a laser beam and transferring the toner onto the paper using thermal induction.

Characteristics: high precision, fast printing speed, suitable for small batch high quality printing.

Applications: office printing, tickets, labels, etc.

4、3D Printing:

Principle: Creates three-dimensional objects by adding materials layer by layer.

Features: Used to produce complex 3D models and prototypes, enabling customized production.

Applications: industrial, prototyping, medical, art, etc.