Cardboard boxes and corrugated boxes are two of the most prevalent types of packaging used across various industries. While they may appear similar at first glance, they possess distinct differences that influence their suitability for different applications.

This article aims to demystify the differences between cardboard and corrugated boxes, providing a comprehensive guide for businesses and consumers alike.

- Material and Structure

- Performance Characteristics

- Environmental Impact

- Cost and Economic Considerations

- Common Uses and Applications

Material and Structure

Cardboard is a versatile and widely used packaging material, known for its single-layer structure composed primarily of thick paper stock or pulp.

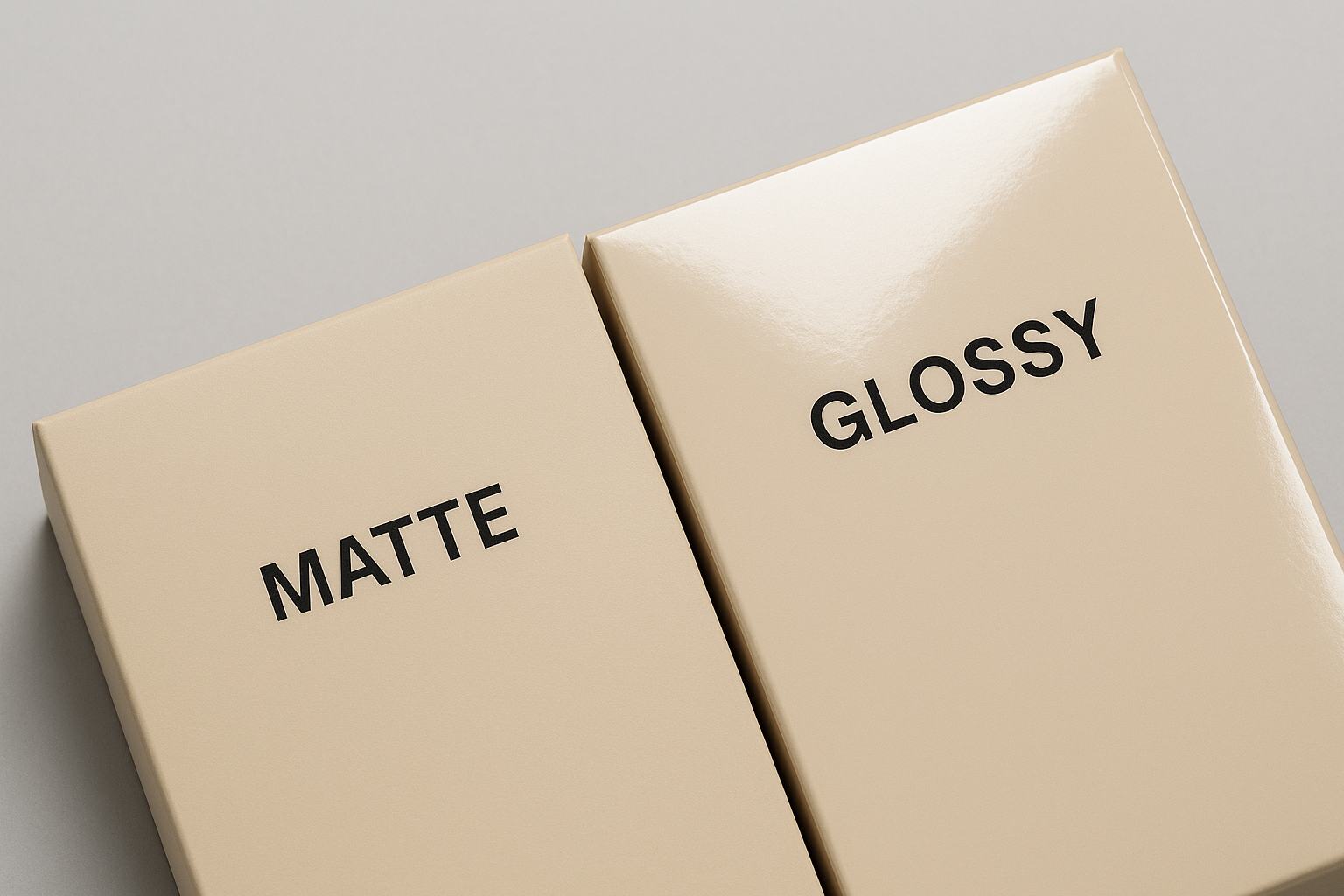

The thickness and density of cardboard can vary, but it generally offers a smooth, flat surface that is easy to cut, fold, and manipulate.

Corrugated boxes are engineered for durability and strength, distinguishing them from regular cardboard. The key component of a corrugated box is its multi-layered structure, which includes an inner and outer liner, with a fluted or wavy layer sandwiched in between. This fluted layer, also known as corrugation, creates air pockets that enhance the box’s rigidity and resistance to crushing.

Performance Characteristics

1.Strength and Load-bearing Capacity

Cardboard, due to its single-layer composition, offers limited strength and load-bearing capacity. It is suitable for packaging light to moderately heavy items that do not exert significant pressure on the box. The material can support items like books, small electronics, and household goods, but it is prone to bending and deformation under substantial weight.

Corrugated boxes, with their multi-layered structure, are designed to handle much higher loads and provide superior strength. The corrugated (fluted) layer between the liners significantly enhances the box’s ability to bear weight without collapsing. Single-wall corrugated boxes can support most standard shipping needs, while double-wall and triple-wall variants can carry extremely heavy or bulky items. This makes corrugated boxes ideal for industrial use, large-scale shipping, and packaging of fragile or valuable items that require extra protection.

2.Weight and Flexibility

Cardboard is relatively lightweight, making it easy to handle and cost-effective for shipping due to lower transportation costs. Its flexibility is a key advantage for various applications, including product packaging, where it can be easily cut, folded, and manipulated into different shapes and sizes.

While corrugated boxes are generally heavier than single-layer cardboard due to their additional layers, they offer a balanced trade-off between weight and strength. Despite their increased weight, they remain manageable and are widely used because of their excellent protective qualities.

3.Resistance to Compression and Impact

Cardboard’s resistance to compression and impact is limited compared to corrugated materials. Under pressure, cardboard can easily bend, crumple, or tear, making it less suitable for heavy or delicate items. While it can protect against minor impacts, it lacks the structural integrity to withstand significant compression forces, which can lead to product damage during shipping and handling.

Corrugated boxes excel in resisting compression and impact due to their fluted inner layer. This design absorbs shocks and redistributes pressure evenly, preventing damage to the contents. The flutes act as a cushion, enhancing the box’s ability to withstand rough handling, stacking, and dropping. This makes corrugated boxes the preferred choice for shipping valuable, delicate, or heavy items.

Performance Characteristics

1.Manufacturing Costs

Cardboard is relatively inexpensive to produce due to its simple, single-layer structure. It is made primarily from recycled paper, which keeps raw material costs low. The production process involves pulping, pressing, and drying the paper, which is less resource-intensive compared to more complex materials.

Corrugated boxes involve a more complex manufacturing process. The production of corrugated cardboard includes the creation of multiple layers: the outer and inner liners, and the corrugated or fluted layer. This process requires specialized machinery and additional materials, such as adhesives to bond the layers. As a result, the manufacturing costs for corrugated boxes are higher than those for single-layer cardboard. However, the increased cost is justified by the enhanced strength and durability that corrugated boxes provide.

2.Cost-effectiveness for Different Uses

For lightweight and low-risk packaging needs, cardboard is often the more cost-effective choice. Its low manufacturing cost and adequate protection for items like food products, cosmetics, and small consumer goods make it an economical option. The ease of printing on cardboard also adds value for branding and marketing purposes, further enhancing its cost-effectiveness for retail packaging.

Corrugated boxes, despite their higher manufacturing costs, offer significant cost savings in scenarios where enhanced protection and durability are required. For shipping heavy, bulky, or fragile items, the superior strength of corrugated boxes reduces the risk of damage during transit, which can prevent costly returns and replacements. Their ability to withstand stacking and rough handling makes them ideal for logistics, e-commerce, and industrial applications.

Environmental Impact

Both cardboard and corrugated boxes are renowned for their recyclability and sustainability, playing significant roles in environmentally friendly packaging solutions. Cardboard, made primarily from recycled paper, is easily recyclable. The recycling process involves breaking down the paper fibers into pulp, which can be reformed into new cardboard products. This cycle can be repeated multiple times, reducing the need for virgin materials and lowering the environmental footprint.

Corrugated boxes are also highly recyclable. The multiple layers of paper used in their construction can be efficiently processed in recycling facilities. The fluted middle layer and the liners can be separated and repurposed into new corrugated material. Many corrugated boxes are made with a high percentage of post-consumer recycled content, further enhancing their sustainability. The robust nature of corrugated cardboard often allows for multiple uses before recycling is necessary, contributing to its eco-friendly profile.

Commom Uses and Applications

Cardboard boxes are widely used for light packaging applications due to their lightweight and flexible nature. Examples of light packaging uses include:

- Food Products: Cardboard boxes are commonly used to package dry food items such as cereal, pasta, and snacks. Their ease of printing allows for attractive branding and nutritional information.

- Clothing and Apparel: Many fashion brands use cardboard boxes to package clothing, accessories, and shoes. The boxes protect the items during shipping while providing a clean and professional presentation.

- Small Electronics: Lightweight electronics like smartphones, headphones, and accessories are often packaged in cardboard boxes. These boxes provide sufficient protection for these delicate items during transit.

Cardboard boxes are also extensively used for a variety of consumer products. Their versatility and cost-effectiveness make them suitable for numerous applications:

- Retail Packaging: Cardboard boxes are used for packaging a wide range of retail products, including toys, games, beauty products, and household items. They offer a balance of protection and presentation, enhancing the overall consumer experience.

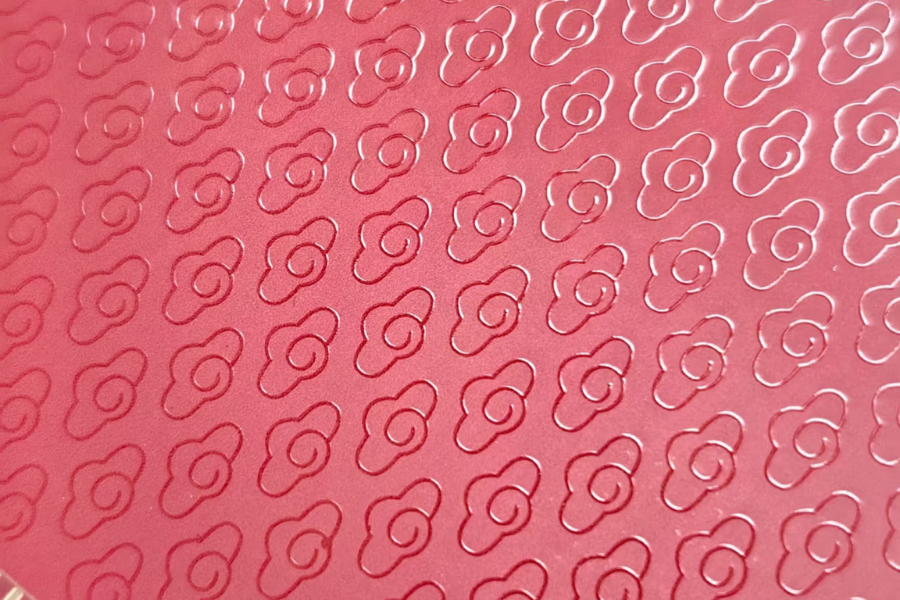

- Gift Packaging: The aesthetic appeal of cardboard boxes makes them a popular choice for gift packaging. They can be easily customized with prints, colors, and embellishments to create attractive gift boxes for any occasion.

- Subscription Boxes: Many subscription services use cardboard boxes to deliver their curated products to customers. These boxes are designed to be sturdy yet lightweight, ensuring the safe arrival of goods while keeping shipping costs low.

Corrugated boxes are the go-to choice for heavy-duty shipping needs due to their strength and durability. They provide excellent protection for items during long-distance transport and rough handling. Examples of heavy-duty shipping uses include:

- E-commerce Shipments: Online retailers use corrugated boxes to ship a wide range of products, from clothing and books to electronics and home goods. The robust construction of corrugated boxes ensures that products reach customers in perfect condition.

- Fragile Items: Products that are easily breakable, such as glassware, ceramics, and electronics, are often shipped in corrugated boxes. The fluted layer within the boxes provides cushioning and absorbs shocks, reducing the risk of damage.

- Bulk Shipping: Businesses that ship large quantities of goods, such as wholesalers and distributors, rely on corrugated boxes to transport their products. The boxes’ strength allows for stacking and efficient use of space in shipping containers and warehouses.

Corrugated boxes are also essential in various industrial applications, where they provide reliable and robust packaging solutions:

- Machinery and Equipment: Heavy machinery parts and industrial equipment are often packaged in corrugated boxes. The boxes protect these valuable items from damage during transit and storage, ensuring they arrive at their destination in working order.

- Automotive Parts: The automotive industry uses corrugated boxes to ship parts and components. The strength and durability of these boxes safeguard the parts from impacts and environmental factors during transport.

- Agricultural Products: Fresh produce, dairy products, and other agricultural items are commonly packaged in corrugated boxes. These boxes can withstand the weight of the products and provide ventilation, maintaining the quality and freshness of the contents.

Choose the Right Box for Your Needs

Key questions to consider include:

- Product Weight and Size: Determine the weight and dimensions of the items you need to package. Heavier and bulkier items generally require stronger and more durable packaging materials, such as corrugated boxes, to ensure safe transport.

- Fragility and Protection Needs: Evaluate how fragile the items are and how much protection they need during transit. Fragile items, such as glassware or electronics, may necessitate the use of corrugated boxes with added cushioning to prevent damage.

- Shipping Distance and Handling: Consider the distance the package will travel and the handling conditions it will face. Long-distance shipping often involves multiple transfers and rough handling, requiring more robust packaging to protect the contents.

- Storage Conditions: Think about the storage conditions for your packages. If the boxes will be stored in a humid or damp environment, moisture resistance becomes an important factor to consider.

- Brand Presentation: For consumer-facing products, the appearance and branding of the packaging can impact customer perception. Cardboard boxes can be easily customized with prints and designs to enhance brand presentation.

In conclusion, understanding the key differences between cardboard and corrugated boxes, along with considering your specific packaging requirements, will help you make informed decisions. As the packaging industry evolves, staying abreast of future trends will enable businesses to adopt innovative and sustainable packaging solutions that meet both their operational needs and environmental goals.

Boost your brand’s presentation with our premium cardboard and corrugated boxes. Reach out to learn more about our custom printing options.